Auction Details

Auction Website

Auction Dates

Auction Start Date

Auction End Date

Preview Information

Preview Date/Time Start

Preview Date/Time End

Preview Special Instructions

Inspection: Monday, Feb 10th, 8am-4pm

Detailed Information

Auction Date: Tuesday, Feb 11th, 11am EST (Webcast)

Inspection: Monday, Feb 10th, 8am-4pm

Location: West Monroe, LA

Featuring:

4 AVAILABLE – 2″ x .134″ Dahlstrom Stainless Tube Mill Lines

- Tube Diameter: .625″ – 2″

- Wall Thickness: .020″ – .134″

- Speed: 90 – 165 inches/min

- 12″ x 2500# Cooper Weymouth Double End Uncoiler (8″ – 20″ Coil ID, 48″ OD, Electric Brake)

- Forming Mill: Model 500-10-08 (Shaft Size: 2.5″)

- Entry Brush De-Burr Unit, 2 Sets of Edge Guides, 5 Forming Stands, 3 Finn Pass Stands, 7 Side Idler Rolls

- 2 Roll Weld Box, Mill Maxstar 700 Tig Welder, Cyclomatic Model 90A Arc Controller, Water Cooler, Hammer Roll Bead Roller

- 3 Sizing Stands, 3 Side Idler Rolls, Turks Head, Flying Abrasive Saw Cut-Off, Run Out Dump Table

- Single Motor Mill, Siemens Simatic HMI Digital Controller, Yaskawa Digital Drive, Siemens Simatic S7-1200 PLC

- 150 KW Ajax Tocco Power Supply, Model Pacer S10

Sunbeam Roller Hearth Bright Annealing Furnace

- Max Operating Temperature: 2200°F

- Furnace Width: 48″, Furnace Length: 30′, Cooling Length: 60′

- Capacity: 5000 lbs/hr Tubing

- 3 Zones, Hydrogen, Nitrogen, Argon Gases

- Atmosphere Engineering Flow Controller, Hydrogen/Nitrogen Atmosphere Controlled

- Cooling Zone with Water Cooled Trays, Seco Warwick Digital Controls, Digital Atmosphere Control Panel

- Entry & Exit Conveyors

1.125 Etna Swedger

- 1.250″ – .280″ Diameter

- Clamping Device, Hydraulic Unit, Tooling

1 3/4″ Mackintosh Hemphill Tube Straightener

- Serial No. 922

- Tube Diameter: 1.750″ – .313″

- 6 Roll Design, Entry & Exit Tables

- Manual Roll Adjustment with Readouts, 2 Motor Drive

Ingersoll Rand Air Dryer

- Model: TMS 0780

- Max Air Pressure: 232 Bar 16

- Min & Max Ambient Temp: 32°F / 115°F

- Max Inlet Air Temp: 131°F

- Design Press: 14.5 PSI (1 bar) to 146 PSI (17 bar)

Gardner Denver Air Compressor

- Model: 2449-436

- 150 HP

- MAWP: 150 PSI @ 250°F

- MDMT: -20°F @ 150 PSI

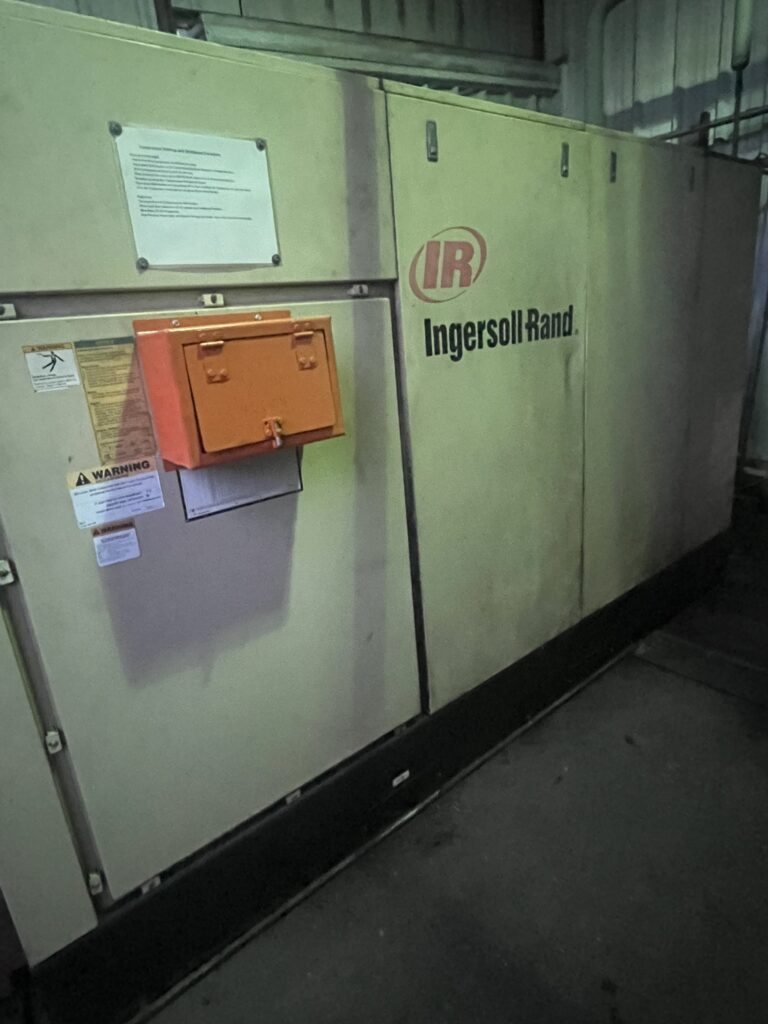

Ingersoll Rand Air Compressor

- Model: SSR-EP150

- Capacity: 670 CFM

- Rated Operating Pressure: 125 PSIG

- Max Discharge Pressure: 128 PSIG

- Drive Motor: 150 HP

300 Ton Evapco Cooling Tower (NEW)

- Model: USS-112-4M14

- Belt No. 6B148

- 2 Armstrong Pumps (Model: 4300-8x8x15-4p-100hp)

- Flow: 1500 USgpm, 100 HP Motor, Max Pressure: 175 PSI

- 1500 gpm pump

#3 Sink Bench/Draw Bench

- Diameter Range: 2 3/8″ – 3/8″, Tube Length: 120′

- Wall Thickness: .020″ – .191″

- Draw Force: 39,345#

- Draw Chain Speed: 209 Feet/Min

- Single Chain, Single Die Block, 250 HP Motor, 3 Snubbers

- Entry & Exit Conveyors, Tooling

#3 Draw Bench Cell

- Diameter Range: 2 3/8″ – 3/8″, Tube Length: 120′

- Wall Thickness: .020″ – .191″

- Draw Force: 48,802#

- Draw Chain Speed: 169 Feet/Min

- Single Chain, Single Die Block, 250 HP Motor

- Entry & Exit Conveyors, Ultrasonic Bar Washer (2021), Wash & Rinse Tanks

- Bar Loader Conveyor, Tube Conveyor, Reeler To Remove Inner Mandrel Bars, Tooling

#2 Sink Bench

- Diameter Range: 2 3/8″ – 3/8″, Tube Length: 120′

- Wall Thickness: .020″ – .191″

- Draw Force: 39,345#

- Draw Chain Speed: 209 Feet/Min

- Single Chain, Single Die Block, 250 HP Motor, 3 Snubbers

- Siemens Panelview 550 Digital Controller, Ultrasonic Tube Wash, Siemens Simatic HMI

- Entry & Exit Conveyors, Tooling

#2 Draw Bench Cell

- Diameter Range: 2 3/8″ – 3/8″, Tube Length: 120′

- Wall Thickness: .020″ – .191″

- Draw Force: 48,802#

- Draw Chain Speed: 169 Feet/Min

- Single Chain, Single Die Block, 250 HP Motor

- Bar Wash, Bar Feed Conveyor, Siemens Simatic HMI Digital Controller

- Reeler To Remove Inner Mandrel Bars From Tubes, Tube Conveyor, Entry & Exit Conveyors, Tooling

Savage Abrasive Tube Cutting Saw

- Capacity: 24″ Wide Layer of Tubes

- Inlet & Outlet Conveyor

- Back Stop, Dust Collector, Spare Blades

- Top & Bottom Clamps

Satec Systems Tensile Tester

- U.T.M Model Vertex 60HVL

- Serial No. 1600 with Instron System ID 60HVL C1600 & Monitor & Printer

Large Amount Of Tooling, MRO, Racking, Welders, Toolroom Equipment & Much More…

Contact: Shawn Gaffney

562-480-3041

shawn@hollandindustrialgroup.com

Checkout Dates: 2/12 – 2/21, 8am – 4pm