SPECS:

MAX. TONNAGE: 20 TONS

MAX. LASER OUTPUT: 3,000 WATTS

LASER TYPE: FIBER

WORKING RANGE:

– PUNCHING MODE X-AXIS: 120″

– PUNCHING MODE Y-AXIS: 61″

– LASER OPERATION X-AXIS: 120″

– LASER OPERATION Y-AXIS: 61″

– COMBINED OPERATION X-AXIS: 98.5″

– COMBINED OPERATION Y-AXIS: 61″

SPEED:

– X-AXIS: 3,543 IPM

– Y-AXIS: 2,362: IPM

– SIMULTANEOUS: 4,252 IPM

– C-AXIS PUNCHING: 330 RPM

– C-AXIS TAPPING: 330 RPM

TOOLS:

– LINEAR MAGAZINE: 22

– NO. WITH MULTITOOL: 22-220

– MULTITOOL: 5/10 STATION

NO. OF SHEET CLAMPS: 3

POSITIONING ACCURACY: (+/-) 0.004″

REPEATABILITY: (+/-) 0.001″

MAX. CUTTING CAPACITY:

– MILD STEEL: 0.24″

– STAINLESS STEAL: 0.24″

– ALUMINUM: .20″

– COPPER: 0.24″

– BRASS: 0.24″

MAX. WORKPIECE WEIGHT: 507 LBS

PART REMOVAL:

– MAX. PART SIZE, PART REMOVAL FLAP, PUNCHING: 19.685″ x 19.685″

– MAX. PART SIZE, FIXED CHUTE PUNCHING (WITH MOVING TABLE): 3.15″

– MAX. PART SIZE, PART REMOVAL FLAP, LASER: 1.96″

APPROX. MACHINE DIMENSIONS WITHOUT GUARDING: 392″(W) x 349″(D) x 98.5″(H)

APPROX. MACHINE WEIGHT: 46.297 LBS

HOURS:

– OPERATING: 11,976

– LASER ON: 8,995

EQUIPPED WITH:

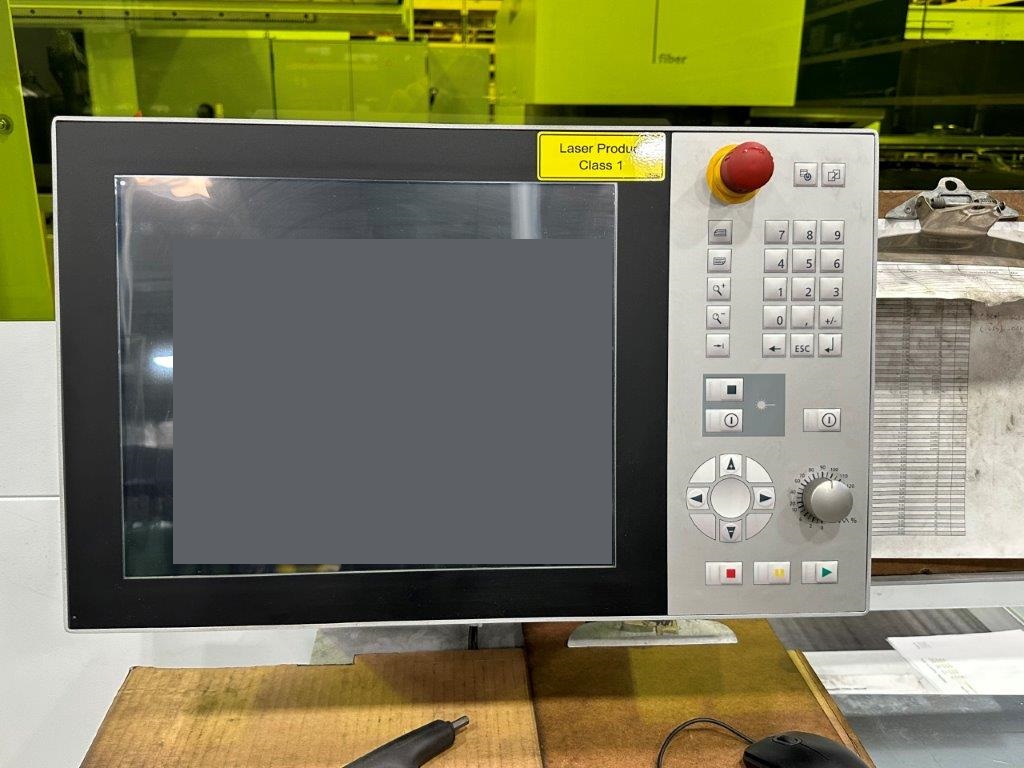

REXROTH INDRAMOTION MTX 17″ TOUCH SCREEN MONITOR

USB CONNECTION AND RJ45 CONNECTION

TRUMPF TRUDISK 3001 3,000-WATT LASER SOURCE

STABLE C-FRAME DESIGN

COORDINATE GUIDE W/INTEGRATED LINEAR MAGAZINE

22) TOOL STATIONS

22) GFP CARTRIDGES INCL. DIE PLATES

3) MATERIAL CLAMPS

PROGRAMMABLE STRIPPER MOVEMENT

VARIABLE VACUUM SLUG REMOVAL AND SLUG BUCKET

PROGRAMMABLE PARTS CHUTE 20″ x 20″ W/PART SENSOR (PUNCH AND LASER CHUTES)

FOOT SWITCH

2) PARTS CONTAINERS

PLASMALINE – SENSOR TO DETECT PLASMA CREATION

PROGRAMMABLE EJECTION CYLINDER ON LASER BRUSH GUARD FOR LASER PART REMOVALS

USB CONNECTION AND RJ45 CONNECTION

MULTI-BEAM LIGHT BARRIERS

EXTRACTION SYSTEM AND COMPACT DUST EXTRACTOR

DIE SPRAY LUBRICATION

AUTOMATIC SHUTDOWN MECHANISM

PRODUCTION PLAN FUNCTION ON MACHINE CONTROL

PARTS CHUTE SENSOR – RIGHT SIDE

ADDITIONAL OPTIONS:

– HIGH SPEED MARKING

– SMART PUNCH MONITORING

– MULTITOOL DRIVE

– WHEEL TECHNOLOGY FUNCTION – FORMING & CUTTING

– STARTUP CONSUMABLE PARTS KIT

– DESCENDING DIE

– INTEGRATED FLATTENING – MUST BUY DESCENDING OR ACTIVE DIE

– TAPPING DRIVE

– BRUSH TABLES

– CHIP/SLUG CONVEYOR WITH BOX

– ANTI-VIBRATION ISOLATION PADS

– WARPED SHEET DETECTOR

– PNEUMATIC REPOSITION CYLINDERS

– STRIPLINE

– DIE SPRAY LUBRICATION

– SMALL PARTS BLOW-OUT DEVICE

– REMOTE START/STOP PEDESTAL

– AIR CUTTING PACKAGE

– COPPER CUTTING PACKAGE

– SHEETMASTER AND GRIPMASTER PACKAGE W/ LOADING STATION

– SHEARMASTER

– PEELING SYSTEM – UP TO 4MM MATERIAL

– ROTOSCANER UNLOAD MONITORING OF LASER CUT PARTS W/ SHEETMASTER

– FIRST STANDARD ADD ON SUCTION GROUP PACKAGE (3 STACKED, 6 SINGLES)

– SECOND STANDARD ADD ON SUCTION GROUP PACKAGE (3 STACKED, 6 SINGLES)

– CONVEYOR BELT FOR PARTS – LASER AND PUNCH SIDE